At the heart of every recovery vehicle lies its most powerful and adaptable asset – the winch. It is the system that transforms a standard vehicle into a recovery platform and delivers the capability to move, lift or recover assets in the most demanding conditions. Without it, even the most capable vehicle is simply a tow truck. With it, a recovery vehicle can deliver decisive capability in the field. That is why understanding how a winch works and how to specify the right one for the task is at the heart of effective recovery planning.

“It’s the winch that puts the recovery in recovery vehicle,” says Michael Keech, MD at EKA. “It is the defining feature that gives a vehicle the ability to do more than move itself. It lets you recover equipment, support operations and maintain momentum in the field.”

Hydraulic power: the backbone of serious recovery:

Winches can be powered in many ways including electric motors, mechanical systems, air and small engines, but hydraulics are best suited to deliver the torque, control and resilience required for military-scale recovery and lifting. Hydraulic systems are capable of sustained pulling and lifting forces, precise speed control and reliable performance in harsh operating environments. This is why they remain the standard for heavy recovery vehicles used by armed forces worldwide.

“Other power sources have their uses, but hydraulic systems give you the combination of strength and control you need for serious recovery,” says Michael. “They are proven, adaptable and capable of dealing with the kind of heavy, continuous loads that come with military operations.”

Pulling and hoisting: application first:

TITAN – Hoisting winch, used on the SV(R)’s crane

The way a winch is used is just as important as its type. Pulling winches are designed to deliver a controlled pulling force and are built to maximise performance and control during recovery operations. Hoisting winches are specified to different standards because lifting presents additional safety demands. These winches must include brakes, higher safety factors and lower cut-out thresholds to ensure loads are always kept within safe working limits.

For many vehicles, both pulling and hoisting capabilities are required. That is why understanding the application comes first. Selecting the right winch for the job means matching performance and safety features to the operational environment.

“Pulling and hoisting aren’t the same thing, even if the equipment looks similar,” Michael explains. “If you get the application wrong you risk poor performance or unnecessary risk. That is why choosing the right type of winch for the task is a technical and operational decision, as it also prevents unnecessary waste of time and money.”

Drum and capstan winches: using the right tool for the job:

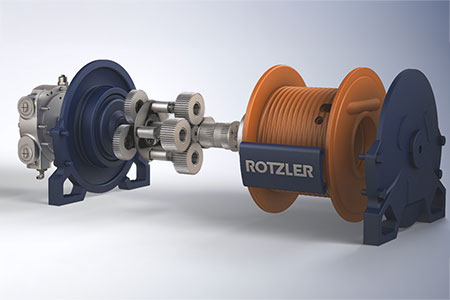

A winch is never just a winch. The right tool for the task depends on what needs to be achieved. Capstan winches, such as the Rotzler TREIBMATIC series, provide continuous pulling power regardless of rope length. They are well suited to controlled recovery pulls because the rope is stored externally and passed over a rotating capstan drum, which maintains a constant pulling force.

Drum winches, by contrast, are more cost effective and versatile. Pulling-type drum winches, such as the ROTZLER TARVOS series and the HZ series, are often used for self-recovery on logistics vehicles. Hoisting drum winches, such as the ROTZLER TITAN and HK series, are designed to meet the safety and certification requirements of lifting operations. Their higher safety factors and cut-out limits protect both operators and equipment.

On many recovery platforms these systems work together, with capstans used for recovery pulling and drum winches providing self-recovery or lifting functions.

Modern control systems and power delivery:

The CrARRV’s TR2000 capstan winch

How a winch is controlled is just as important as the hardware itself. Traditional recovery platforms relied on manual levers at the valve block to operate the winch. Today modern CAN-Bus control systems allow multiple winches to be operated precisely and simultaneously. This means operators can control both pulling and lifting functions at once, position themselves safely and carry out complex recoveries with greater accuracy.

“Modern control systems are one of the biggest step changes in how winches are used,” Michael says. “Being able to manage several functions at once from a safe distance transforms how operators work. It is about control, safety and capability coming together.”

This evolution in control reflects the operational reality of modern recovery. It is not simply about brute force but about coordinated, safe and efficient use of equipment.

Performance considerations:

A key part of winch performance lies in understanding the relationship between torque, drum size and rope layers. This applies specifically to drum winches. On the first layer of rope the effective radius of the drum is smallest, so the pulling force is greatest. As layers build up the radius increases, the mechanical advantage reduces and pulling force falls. This is why rated pulling power is always measured on the first layer.

Operators can use mechanical advantage to boost performance. A single snatch block used in a 2:1 configuration doubles the line pull; this can be critical when recovering immobilised vehicles or working with maximum loads.

Integration and safety:

In practice a winch is rarely a stand-alone component. It is part of an integrated system that combines multiple winches to meet different operational needs. Capstans may be used for main recovery tasks, pulling drum winches for self-recovery or auxiliary functions, and hoisting winches as part of crane systems.

Safety is built into every stage of system design. Over-speed protection prevents the drum from rotating too quickly under load. Automatic brakes hold the rope when controls are released. Slack rope sensors help avoid tangling and pressure relief valves protect the hydraulic system. Hoisting winches also incorporate additional safeguards to meet their specific safety and certification requirements.

EKA’s expertise:

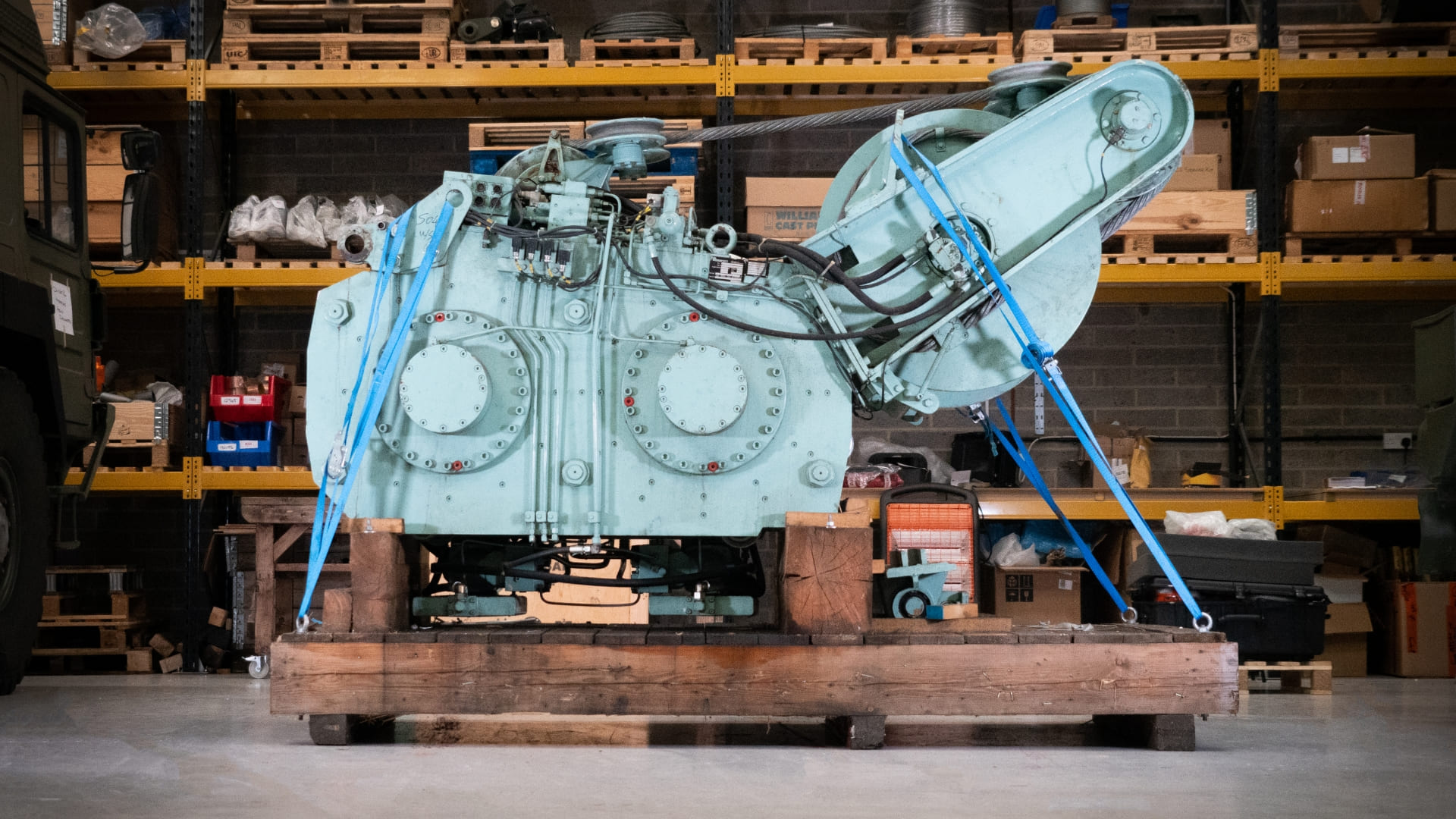

EKA has extensive experience integrating ROTZLER winches onto military and specialist platforms. Typical configurations often include multiple winches, each serving a distinct purpose. Auxiliary winches are used to assist the deployment of the main winch, especially across difficult or uneven terrain. Self-recovery winches enable the vehicle to free itself when immobilised, while main winches handle the recovery of other vehicles or the loading of heavy equipment onto trailers. Additionally, Titan crane winches are employed for lifting operations. Platforms such as the SVR and MLRS Repair and Recovery Vehicle demonstrate how multiple winches can be integrated to meet complex operational requirements.

“What sets us apart is that we don’t just supply winches,” Michael concludes. “We design and integrate them into our special to role equipment so they deliver real capability. That means thinking about control, safety, logistics and the operational reality of how they will be used in the field.”

This experience means EKA understands not only the hardware but how to configure complete systems that deliver capability where it matters most.

Getting it right from the start:

A winch turns a recovery platform into a decisive asset. Choosing the right system and integrating it properly determines whether that capability can be delivered safely and effectively in the field. That is why EKA works closely with industry partners to provide proven, adaptable and technically sound winch solutions that match the real demands of recovery operations.