Developing a modern recovery vehicle isn’t just an engineering challenge – it’s a commercial balancing act. From concept to delivery, organisations like EKA must navigate a dense web of regulatory constraints, economic pressures, and legacy procurement practices – all while ensuring the final product performs in the toughest real-world conditions.

Meeting today’s military recovery requirements means designing vehicles that are capable, compliant, and cost-effective – all at the same time. But success isn’t just about meeting a written specification. It’s about understanding what that specification is trying to achieve, anticipating how it might evolve, and building a platform that’s ready for the demands of tomorrow as well as today.

“Our role is to manage those trade-offs and deliver a system that works – for the user, the environment, the mission and the budget” said Andrew Kelly, Operations Director at EKA. ”Commercial success in this space is about more than technical compliance. It’s about delivering a solution that’s not only capable now, but adaptable to what comes next. In five years’, when new vehicles are introduced or existing fleets are modified, the recovery system still needs to work. That means understanding the operational environment, anticipating how it might evolve, and designing for the gaps that often exist between the written specification and real-world usage.”

Physics always wins

SVR lifting a US Stryker

Unlike budget, timelines or requirements, Newton’s laws are non-negotiable. Recovery vehicles operate at the limits of axle loads, winch forces, traction and anchor integrity. They must be stable while towing, resilient across different types of challenging terrain, and able to recover heavily armoured casualties that may be immobilised, damaged, or unevenly loaded.

“Even experienced customers can overlook how a single design decision ripples through the whole vehicle”, said Andrew. “Recovery platforms are governed by physics – mass, geometry, load distribution – and every change has consequences. A larger winch or crane, for example, might require chassis reinforcement or affect axle compliance. These aren’t theoretical issues – they shape everything from mobility and reliability to cost and maintainability.”

This becomes even more relevant when dealing with heavier, more complex platforms like Boxer, Tyro, Archer or the newer Multi-Launch Rocket System (MLRS) fleet, where recovery scenarios must account for asymmetric weight distribution, higher centre of gravity, and limited ground clearance.

“You can’t forget the fundamentals,” Andrew added. “Our job as subject matter experts is to deliver optimum winching capability in a range of challenging ground conditions – whether that’s soft soil, hard standing or anything in between. Movement under load is expected; the question is whether the system manages it safely and effectively.”

Cost and capability: the tightrope walk

Even when the complex physics of recovery are resolved, commercial viability adds another challenge. This is where EKA’s specialism comes into its own. Delivering a technically capable vehicle is one thing – delivering it in an increasingly challenging commercial environment is another.

From fluctuating raw material costs and currency volatility to layout constraints and component availability, EKA constantly tailors its solutions to protect performance, cost and compliance. It’s not about chasing perfection – it’s about applying experience and judgement to deliver the best possible solution, every time.

Every feature has a cost multiplier. Adding a winching capability will require chassis strengthening and integration with the host platform, which might also involve additional modifications. Fitting a crane might affect stowage layout or axle load compliance. Each decision must consider performance, reliability, and the long-term impact on the vehicle’s operational effectiveness.

“Recovery vehicle specifications are often developed in good faith to cover every conceivable need,” said Michael Keech, Managing Director at EKA. “But integrating all those requirements into a compliant, road going platform introduces real complexity. The more capability you build in, the more important it becomes to manage the trade-offs carefully – and that’s where our expertise adds real value.”

EKA designs systems to be easy to operate, but that simplicity hides a significant amount of engineering effort. Winches must be mounted to allow safe, accessible rope exits. Stowage is laid out to support intuitive operation under pressure. Safety systems must be clearly visible and easy to reach, even in low light or poor weather. And just as importantly, every system must account for human factors – where the operator stands, how they move, and how they stay safe while doing the job.

EKA is delivering technically complex systems that feel simple to use, even under duress and in extreme environments, which are also compatible with other battlefield assets. That integration takes deliberate, detailed work and it’s what sets military recovery vehicles apart from their civilian counterparts.

Compliance and the cost of doing it right first time

The regulatory landscape for military vehicle development is extensive, spanning DEF STAN, STANAG requirements, MIL-STD, and regulations like LOLER and PUWER. These standards aren’t in conflict, but meeting them together often requires specialist solutions. While commercial off-the-shelf equipment can offer cost and availability advantages, ensuring full compliance with defence requirements often demands additional engineering. This is where specialist design expertise becomes essential.

Rigorous testing is essential because military recovery vehicles must prove their reliability and safety under a range of demanding conditions. That process takes time, specialist facilities, and detailed preparation. Some test programmes can take months and run into hundreds of thousands of pounds, but that’s the cost of doing it right. EKA’s job is to ensure each platform is ready – not just to pass the test, but to perform in the real world it represents.

Andrew said: “We’ve seen scenarios where the cost of the test facility matches that of the system under evaluation. But that’s the nature of delivering military-grade equipment. You either prove it works, or you don’t deliver.”

Post-Brexit, importing components from the EU or the US has become more complex, with added customs requirements, origin tracing, and the potential for shipping delays. These factors can affect timelines and approvals, particularly for systems that need to meet strict military regulations. But this is exactly where a specialist contractor adds value. It’s EKA’s job to manage these challenges, and we’ve built the processes, partnerships, and experience to keep projects moving regardless of complexity.

The international regulatory picture is evolving too. ITAR (International Traffic in Arms Regulations) — the US law governing the export of defence-related items — continues to shape sourcing decisions across global defence programmes. There’s a growing desire in the UK and EU for ITAR-free equipment, particularly when it comes to sovereign manufacturing and supply and long-term supportability.

As a dedicated military supplier, EKA recognises this shift and continually adapts to stay ahead of the regulatory curve, ensuring solutions delivered are not just compliant today, but future-proofed for tomorrow’s procurement landscape.

The Statement of Work dilemma

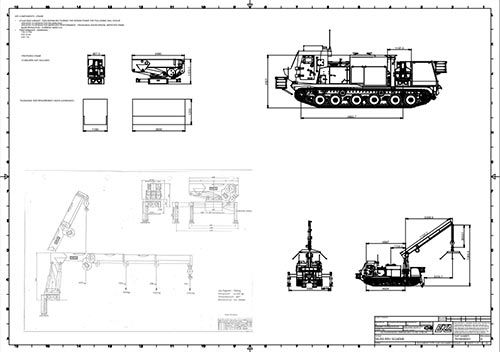

MLRS RRV concept example

One of the greatest challenges in delivering modern defence programmes isn’t technology or cost, it’s confirmation bias. Many Statement of Work (SOW) documents are shaped by legacy systems and long-held assumptions. They reflect what’s worked before, not necessarily what’s best now.

“We’ve received SOWs that clearly reference platforms from the 1990s,” said Andrew Kelly. “But technology, mission needs, and user expectations have all moved on. Our role is to take what’s worked before and evolve it — so the solutions we deliver are right for today, and ready for tomorrow.”

Often, the issue isn’t that the specification is technically flawed — it’s that it’s based on inputs and design patterns from earlier platforms. Layouts, payloads, and systems are sometimes carried forward by default, even when newer technologies offer more effective alternatives. This can constrain design flexibility and delay the adoption of improved capabilities.

EKA’s aim is to support better outcomes by engaging early in the process — offering practical, experience-based options that align with both legacy needs and future requirements. It’s not about tearing up the specification but working with it to deliver the best possible solution.

UK content vs global performance

Many UK defence programmes now include a formal UK content requirement, typically a percentage target for components, subassemblies, and labour sourced domestically. EKA supports this drive toward sovereign capability, but the availability of specialist or high-performance subsystems from overseas highlights the ongoing need for investment in UK manufacturing capacity.

Some of the most capable hydraulic, electrical or control systems may be produced in countries like Germany, Spain, Italy or the US. In these cases, EKA must weigh whether the increased complexity of importing those systems – including added scrutiny, paperwork, and regulatory compliance – is justified by the capability they deliver in a UK military context.

This becomes particularly significant during competitive tenders, where UK content is often a scored criterion. Suppliers who can demonstrate a high percentage of UK content are placed at a clear commercial advantage. Even when imported systems offer proven performance, relying heavily on overseas components may reduce competitiveness or create tension during bid assessments.

EKA is actively supporting the shift from a model of high reliance on imported technology to one that prioritises UK-based manufacturing and assembly. By increasing the tangible value added in the UK, EKA, and other similar SMEs, are better able to meet the demanding content requirements set out in today’s defence programmes.

Michael said: “UK content isn’t about compromise, it’s about delivering best-in-class equipment – while building the partnerships, processes and skills that bring more of that value into the UK. That’s part of our job as a defence supplier, and it’s something we invest in continuously.”

EKA invests heavily in local partnerships and UK-based manufacturing capability, working with trusted subcontractors and bringing as much value into the domestic economy as possible, while still maintaining the performance standards required by end users.

Through-life value: the hidden differentiator

One area often overlooked in procurement is the long-term sustainment model. EKA’s engineering capability is matched by its ability to provide ongoing support – whether it’s spares, training, refurbishment or system upgrades. This through-life approach allows them to design with sustainability, durability, supportability and maintainability in mind from the outset.

“Knowing we’ll be supporting the platform through life sharpens our focus,” Michael Keech explained. “It pushes us to design for maintainability, simplify repairs, and use common parts wherever possible – because we know those choices will pay dividends over time.”

In tight fiscal environments, that kind of through-life thinking becomes a commercial asset – hard to quantify in a bid, but critical to operational value.

Obsolescence: the clock is always ticking

Technology moves fast, sometimes faster than the procurement cycle. What’s cutting edge in a bid response may be outdated before a vehicle reaches production. Nowhere is this more evident than in electronics.

CAN-Bus integration, power management, lighting systems, diagnostic displays – all of these components are evolving constantly. Yet many platforms being developed today are tied to assumptions made years ago.

“Obsolescence is part of the lifecycle, especially in areas like electronics and control systems,” Andrew explained. “So, we don’t try to avoid it — we plan for it. Whether it’s hardware, software, or control units, we design our platforms to be supportable, upgradeable, and resilient to change. That way, we can manage the impact of obsolescence long before it becomes a problem in the field.”

Obsolescence management at EKA is treated as a necessary overhead, an investment in future reliability. Designing military equipment that remains supportable over time takes careful planning, strong supplier relationships, and attention to detail. But it’s time and money well spent early in the development cycles, to avoid higher costs and longer delays later in the platform’s life.

Smarter collaboration, better results

For EKA, the way forward is built on partnership – not just with suppliers, but with both customers and end users, including soldiers on the ground. Early engagement creates more opportunities to shape outcomes, reduce costs, and avoid engineering dead ends. This kind of collaboration is already becoming standard in other sectors and there’s no reason recovery vehicle development should be any different.

“The best vehicles we’ve ever delivered came from honest collaboration at the requirements stage,” Michael concluded. “It’s where we can save the most time, cost and complexity – before we’ve even made a concept or drawing.”

Initiatives like the Defence Innovation Fund and the Defence Growth Board aim to drive more agile procurement and SME engagement, but success still depends on collaboration at the specification stage – where real-world performance and cost can be aligned from the outset.

Bringing engineering and economics together

The commercial and engineering challenges of developing a recovery vehicle are closely intertwined. Building a platform that performs under pressure and remains efficient through life requires careful trade-offs, innovation and clarity at every stage – from contract requirements to supplier engagement.

EKA is helping bridge that gap. By aligning practical engineering with commercial realism, and challenging outdated assumptions in procurement, it’s not just building recovery vehicles, it’s building smarter ways to deliver and maintain them. This is smart delivery under pressure and it’s what EKA does best.