In modern warfare, vehicle mobility is as important as firepower. If an armoured vehicle is immobilised due to mechanical failure or battlefield damage, it can be a strategic liability – not just for the mission, but for the personnel it carries. A stranded vehicle isn’t just an asset out of action; it can put soldiers at risk, making them vulnerable to enemy fire, environmental exposure or supply chain disruptions.

Recovery is not simply about moving an asset from one point to another; it is about sustaining lethality and force mobility, ensuring operational tempo, and maintaining tactical advantage.

Military recovery crews operate in environments where infrastructure is degraded, terrain is unpredictable, and time is critical. As such, recovery systems must be rapid, adaptable, and designed for real-world combat conditions.

EKA’s managing director, Michael Keech, is clear about what works: the right system already exists, and it’s suspend tow. It is a proven, field-tested solution that supports effective recovery operations while maintaining vehicle mobility. The challenge is ensuring that the best system is deployed at scale to support mission objectives.

“We’re not here to reinvent the wheel,” Michael explained. “Suspend tow has been tested, proven, and trusted in military operations. The issue is not capability – it’s that more decision-makers need to recognise why this is the most effective solution.”

Why suspend tow is the superior choice in military recovery

Recovery professionals know that not all systems are created equal. While underlift is widely used in civilian recovery, it presents operational challenges in military applications.

Underlift systems use a large boom and fork mechanism that extends underneath a vehicle before lifting it. This is suitable for controlled environments (such as public roads in civilian applications), but in military operations, it introduces complications that can reduce efficiency and increase risk. It is difficult to deploy on undulating terrain or where space is limited and adds unnecessary bulk and weight to the recovery vehicle.

Key challenges with underlift in military recovery include:

Key challenges with underlift in military recovery include:

- Time-consuming deployment: Underlift systems require precise positioning and setup, delaying vehicle extraction and extending operational exposure to recovery crews, who could be working in hostile and kinetic environments.

- Compromised mobility: Underlift equipment adds weight to recovery vehicles, reducing their ability to navigate off-road conditions effectively.

- Terrain limitations: Steep inclines, soft ground, and debris-filled terrain on battlefields make underlift impractical. Recovery crews need a system that works anywhere.

- Limited suitability for combat-damaged vehicles: If a vehicle has sustained structural or drivetrain damage – underlift is less likely to be a viable option.

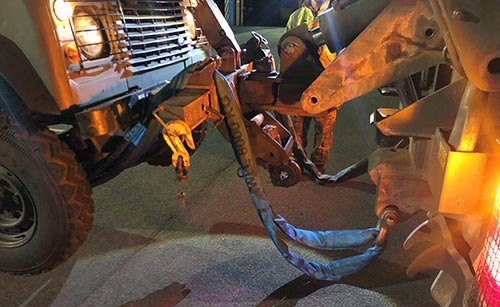

Suspend tow solves these problems with a battlefield-ready system designed for rapid extraction in any terrain. Instead of a bulky lifting mechanism, it uses a recovery bar with interchangeable adaptors that quickly attach to different vehicles. The process is simple:

- Extend the recovery bar from the recovery vehicle.

- Connect via recovery adaptors to the casualty vehicle’s recovery eyes, chassis, axle, or suspension.

- Lift and tow – ensuring minimal delay in recovery operations.

When a vehicle is severely damaged and standard attachment points are no longer available, the highly adaptable chain lift configuration can be used to connect the recovery bar to an axle or the remaining chassis structure. This ensures that even vehicles with catastrophic front-end damage can still be safely extracted and secured for recovery.

A NATO-standard system built for interoperability

Suspend tow is not just effective; it is battle proven across multiple theatres of operation, and it has been successfully deployed on European and NATO-led exercises, confirming its interoperability between allied forces. In multinational operations, standardised recovery methods are critical, as different military forces operate a wide range of vehicle types.

Michael continued: “Suspend tow has already been successfully utilised in conflict environments, and is currently deployed on NATO multinational operations, supporting interoperability across allied recovery units. Standardisation is key to effective joint operations, and this system delivers.”

Why mobility is the key to battlefield recovery

The ability to reach and extract a damaged vehicle is just as important as the ability to tow it. If the recovery system itself limits operational mobility, it can compromise the success of an entire mission.

Underlift systems add significant weight and bulk to recovery vehicles, which in turn reduces their agility and capability in off-road environments. This is a major issue in modern conflicts, where recovery crews routinely operate on unprepared ground, on mud & impact-damaged roads, steep inclines, and unpredictable terrain.

Some of the most common mobility issues caused by underlift include:

- Reduced manoeuvrability: Additional weight negatively impacts steering precision, particularly in soft ground or confined operational spaces.

- Weight imbalance when towing: Underlift adds extra weight at the back of the recovery vehicle, lifting the front end and affecting steering and suspension. This can make handling unpredictable and managing axle weights more challenging.

- Increased risk of failure on difficult terrain: If a recovery vehicle gets stuck before reaching its target asset, the mission is over before it starts.

- Higher wear and maintenance costs: Underlift systems put excess strain on the rear axles of the recovery vehicle. Over time, this leads to increased maintenance costs, reduced lifespan, and even a greater risk of the recovery vehicle itself becoming immobilised. The added stress on axles and suspension makes underlift not just a tactical liability, but a long-term operational burden.

Modern armoured vehicles like Boxer, TYRO, and Challenger 3 are heavier than ever, pushing traditional recovery vehicles to their limits. Adding an underlift system only makes this problem worse, increasing axle loads, reducing traction, and limiting mobility.

Michael commented: “If a recovery vehicle is already carrying excess weight before it even reaches the casualty, you’re creating more challenges than solutions. Suspend tow is designed to support force mobility – not hinder it.”

Military planners must factor long-term operational efficiency and fleet longevity into procurement decisions. Suspend tow isn’t just a recovery solution; it is an investment in mission readiness and vehicle sustainability.

Designed for mission efficiency

Military recovery requires equipment that is:

- Rapid and simple to deploy: No complex lifting mechanisms, no unnecessary setup, no wasted time.

- Lightweight and efficient: No unnecessary weight slowing the vehicle down, keeping mobility as high as possible.

- Capable of handling extreme damage: Systems must function even when conventional attachment points are compromised.

Underlift systems, while useful in civilian recovery on soft skinned vehicles, do not meet these requirements.

“Military recovery isn’t about controlled environments or commercial applications,” Michael said. “This is about maintaining force capability and ensuring that recovery crews can perform their role in any scenario.”

The future of military recovery: scalable, adaptable, and effective

There is no one-size-fits-all solution for military recovery. The future lies in modular, adaptable recovery systems that can operate effectively across a variety of mission profiles.

- Suspend tow is part of a scalable and adaptable fleet of recovery solutions that can handle both routine breakdowns and complex battlefield extractions.

- It integrates seamlessly with winching operations, minimising the need for additional equipment and reducing logistical burden.

- It reduces axle stress and wear, increasing the service life of recovery vehicles and lowering long-term maintenance costs.

As military vehicle technology evolves, recovery systems must evolve alongside them. The increasing use of electric and hybrid platforms presents new challenges, particularly regarding weight distribution and drivetrain protection. Suspend tow offers a versatile, low-impact solution that accommodates future fleet developments.

Michael concluded: “Suspend tow isn’t a theoretical concept – it’s a proven system that has been tested in real operational environments. The recovery community understands why this works. The challenge now is ensuring wider adoption where it’s needed most.”